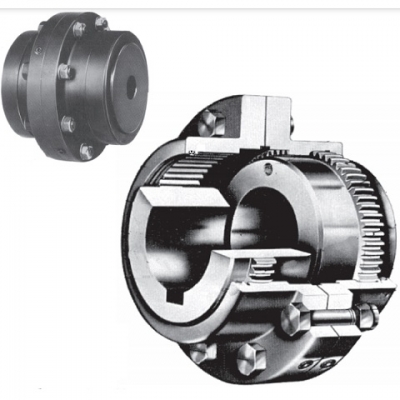

Lovejoy Gear Coupling

FEATURES

Less Backlash.

Compact Assembly.

Larger Bore Capacities.

High Power To Weight Ratio.

Accommodates Angular, Parallel & Axial Misalignments.

Generally used up to 120*C. Can be used for higher temperatures by using the proper grade of grease or oil.

CONSTRUCTION

Full gear type LFG Lovejoy Flexible Gear Coupling consists of two identical toothed hubs, two identical flanged sleeves with internal teeth, a gasket, a set of bolts, nuts and lock washers, lube plugs, and two oil/ grease retaining seals over the hubs.

NOMENCLATURE?

FORGED HUBS WITH EXTERNAL TEETH?

FORGED SLEEVES WITH INTERNAL TEETH

FLANGE GASKET

CLOSE TOLERANCE CONNECTING BOLTS

LUBRICATION PLUG?

O’ RING

SELECTION PROCEDURE

Select an appropriate SERVICE FACTOR from the table given below.

Multiply the rated running power by the service factor. This gives DESIGN POWER at a rated speed (rpm). Convert this to design power at 100 rpm. This is used as a basis for coupling selection.

Refer to the rating column and read until the power greater than or equal to the design power at 100 rpm is found. The size of the gear coupling is given in the corresponding first column. Check the max. bore capacities. If the required bore size is greater than the max. the bore of the selected coupling size, then go for a higher size to meet the required bore.

FEATURES

Standard full flexible gear coupling TYPE LFG accommodates angular & parallel misalignments or a combination of both as well as axial misalignment (end float). Ideal for all horizontal, close coupled applications including fans, overhead cranes, conveyors, and steel & paper mill equipment. One or both of the hubs can be easily reversed for more than normal shaft separation applications.